Microstructural Characterization of Shape Memory Alloys

Under the appropriate stress and thermal conditions, Shape Memory Alloys (SMAs) exhibit the ability to fully recover large deformations. The Shape Memory and Superelastic behavior of these alloys are often utilized in unique design applications. For example, the medical field currently utilizes Nickel-Titanium alloys for a surgically implantable stent device that expands to support damaged or weakened arteries. The unique performance of this class of materials is governed by a thermally reversible crystallographic phase transformation (Austenite - Martensite).

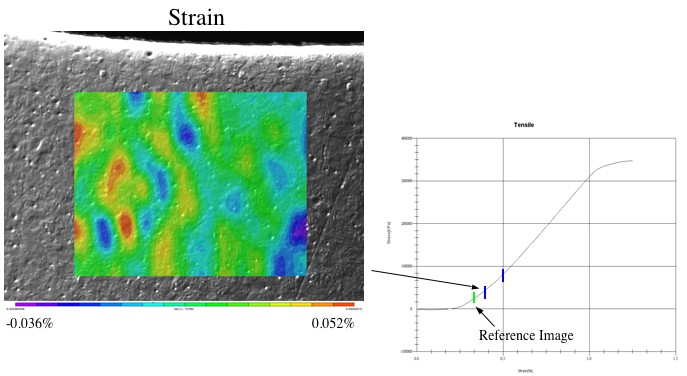

In part of our research on SMAs, the macro- and microscopic response of these materials is analyzed using a Digital Image Correlation (DIC) technique. In general, the DIC method tracks the location of points from a reference image and compares them to the location of those same points in a new, deformed image. Collecting quantifiable data from images is not an entirely new concept. However, with recent advances in personal computers and digital imaging, DIC has emerged as a powerful tool that has the capacity to map 2-D deformation measurements under a large range of time scales and at nearly any length scale. Similarly, the appeal of DIC techniques lie in their ability to improve upon the average displacement data given by traditional electrical resistance strain gages and instead provide local measurements across an entire specimen. Figure 1 shows a calibration of DIC on a polyethylene sample using a speckle pattern as markers.

In our experiments, digital images are taken of the test samples during uni-axial tension tests both with, and without, an optical microscope. The digital images are processed through a series of search algorithms that track the movement of visible features on the surface of the test sample. The goal of this study is to characterize SMAs by mapping the evolving strain fields during the Martensitic phase transformation at both a global and local scale, first for monolithic SMAs (Figure 2) then for porous SMAs. Existing search and track algorithms fail to account for new features in an image that arise during the Martensitic transformation. Current work is directed toward adopting DIC methods for use on SMAs through improved experimental techniques and modified search algorithms.