Synthesis and Characterization of Nanoreinforced Polymers

Our primary research interest is developing multi-functional polymer nanocomposites using different nanofillers as reinforcement in polymers. Two difficulties that have been identified in polymer nanocomposites are nanoparticle aggregation and achieving strong polymer matrix-nanoparticle interaction. To address these issues and achieve the target properties, a major focus of our work is surface modification of the nanoparticle for the desired polymer system. Characterization of the nancomposites includes mechanical, thermal and electrical properties. We use time and temperature dependent viscoelastic properties to probe the influence of the nanoparticle on molelcular mobility and the interphase zone and its percolating changes on bulk material response. Electrical properties provide information about the dispersion of the particles in the matrix, as well as insight into the formation of nanoparticle contact percolation networks. Thermal gravimetric analysis is used to determine the stability of the nanocomposites and chemical analysis is used to verify functionalization strategies. In addition to the varied characterization techniques, our group studies a wide variety of nanoparticle systems. Currently, the nanoparticle systems used in our research include carbon nanotubes (SWCNT, MWCNT, DWCNT), graphite nanoparticles, C60, carbon nanofibers and metal/metal oxide nanoparticles. These varied particles provide a large spectrum of materials properties including: size, shape, surface groups, mechanical and electrical properties of the nanofillers. One critical component of polymer nanocomposite creation is the processing techniques. The selection of a particular technique can have profound influence on the properties of the final product. The processing techniques explored in our work include solution-based methods, shear mixing, solid state shear pulverization (collaboration with J. Torkelson), and twin-screw extrusion

Functionalization of carbon nanotube and their influence of nanocomposite properties:

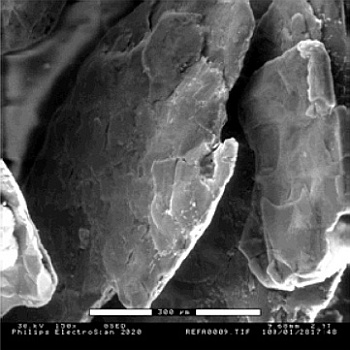

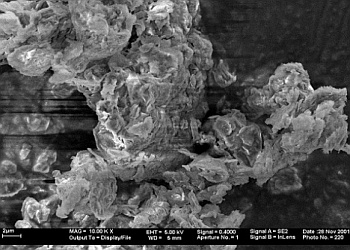

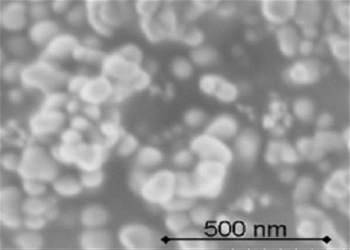

Chemical functionalization of CNTs, which enables covalent chemical bonding between CNTs and the polymer, has been proposed as a way to enhance the interface and load-transfer in nanotube-polymer composites. An additional advantage is that functionalized nanotubes are easier to disperse in organic solvents, which can improve the dispersion of CNTs in polymers (e.g., Journal of Polymer Science: Part B Polymer Physics, 2006). We have successfully functionalized SWCNTs by introduction of an amino moiety on the SWCNT surface through approaches of amide and amine functional groups, as shown in figure 1 (Ramanathan et al Chemistry of Materials, 2005).

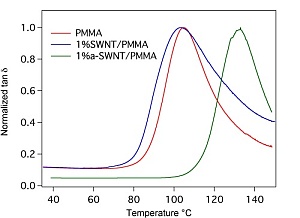

Temperature sweeps in dynamic mechanical (DMA) response show that the glassy state storage modulus of modified SWCNT /PMMA composites are significantly higher than that of the neat polymer. The strong influence of the interfacial region is clearly evident from the glass transition temperature (Tg) shift, as shown in Figure 2 where tan d is plotted against temperature for functionalized SWCNT/PMMA composites. In frequency domain time-temperature superposition can be used to show differences between the viscoelastic behavior of nanocomposites and the parent polymer system.

Researchers on this project:

Collaborators:

Linda Schadler

Ken Shull

John Torkelson

Publications:

Amino-functionalized single-walled carbon nanotube for binding to polymers and biological systems. T. Ramanthan, F. T. Fisher, R. S. Ruoff and L.C. Brinson, (Chemistry of Materials, 2004, 17, 1290)

Functionalized SWNT polymer nanocomposites for dramatic property improvement, T. Ramanthan, H. Liu., and L.C. Brinson, (Journal of Polymer Science: Part B:Polymer Physics, 2005, 43, 2269)

Apparent enhanced solubility of single-wall carbon nanotubes in a deuterated acid mixture. T. Ramanthan, F. T. Fisher, R. S. Ruoff and L. C. Brinson, (Research Letters in Nanotechnology, 2008)

Graphitic nanofillers in PMMA nanocomposites—An investigation of particle size and dispersion and their influence on nanocomposite properties, T.Ramanathan, S. Stankovich, D.A. Dikin, H. Liu, H. Shen, S.T. Nguyen and L.C. Brinson (Journal of Polymer Science: Part B: Polymer Physics, 2007, 45, 2097)

Functionalized Graphene Sheets for Polymer Nanocomposites, T. Ramanathan, A. Abdala, S. Stankovich, D.A. Dikin, M. HerreraAlonso, R.D. Piner, D.H. Adamson, J. Liu, R.S. Ruoff, S.T. Nguyen, I.A. Aksay, R.K. Prud’homme and L.C. Brinson, Nature: Nanotechnology, 2008, 3, 327)